Supply chains across Australia and New Zealand (ANZ) have faced intense pressures in recent years. Disruptions from global events, capacity constraints and shifting consumer behaviour have exposed inefficiencies.

To combat these challenges, forward-looking ANZ companies are seeing their supply chain as an opportunity, with a recent survey finding that 57 percent of respondents confirm the C-suite is more focused on supply chains.

As a result, these companies are investing in supply chain optimisation initiatives designed to build new competencies, expand market share and develop an advantage that isn’t easy for competitors to replicate.

And for many, they are turning to NetSuite and its diverse supply chain solutions to bring together procurement, inventory management, demand planning and warehouse operations under a single system.

This guide dives into the evolving complexities of modern supply chains and reveals how cloud ERPs like NetSuite empower ANZ businesses to stay ahead through smarter, more agile optimisation.

More signs of a shift toward strategic supply chain management

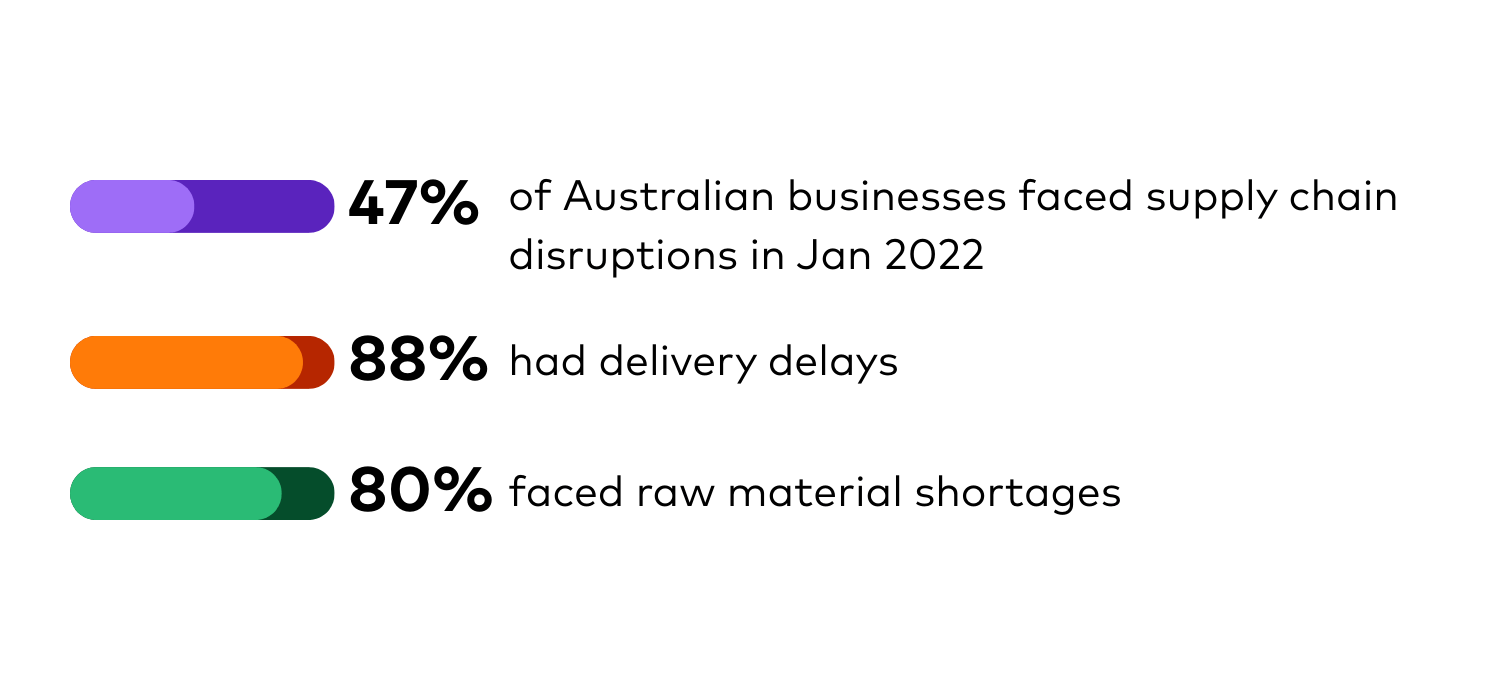

The past few years have been a wake-up call for supply chain leaders. According to the Australian Bureau of Statistics (ABS) Business Conditions and Sentiments Survey, 47% of Australian businesses reported supply chain disruptions in January 2022. Among those affected:

- 88% experienced delivery delays, both domestic and international.

- 80% struggled with supply constraints for raw materials and goods.

These challenges led to widespread operational inefficiencies, rising costs and missed revenue opportunities.

With supply chain leaders increasing their supply chain technology and innovation investments to improve visibility and agility, many are turning to NetSuite’s cloud-based supply chain solutions, and the reasons are many.

Benefits of optimisation and the role of modern ERP

Optimising the supply chain yields tangible benefits across all industries – from cost savings and higher productivity to improved customer satisfaction.

Cost reduction | Streamlining supply chain processes directly cuts operational costs. Companies with optimised supply chains spend significantly less on freight, warehousing, and inventories relative to sales. Best-in-class organisations can reduce total supply chain costs by eliminating waste – such as excess stock and redundant handling – and by negotiating better supplier terms via data-driven procurement.

Faster delivery & responsiveness | An optimised supply chain is an agile one. Shorter lead times mean companies can respond quickly to customer demands or market changes – like ramping up production of a hot-selling item. In retail, faster fulfillment prevents lost sales. For manufacturers, agility means being able to adjust production schedules with minimal downtime when orders fluctuate.

Improved reliability | Optimisation leads to more reliable operations. ‘Perfect orders’ – right product, place, time, quantity – become more common. Customers notice this in fewer stockouts and backorders. Better forecasting and inventory planning help too by, for example, improving on-time delivery metrics and fill rates. Ultimately, consistency builds trust with customers and partners – for example, distributors that consistently deliver in-full and on-time become preferred suppliers.

Better cash flow and working capital | When inventory is optimised, cash isn’t unnecessarily tied up on shelves. Faster order-to-cash cycles mean businesses generate revenue and get paid sooner. Also, reducing average inventory levels frees up capital that can be used elsewhere.

Resilience to disruption | Perhaps most critically, an optimised supply chain is more resilient. By having better visibility and contingency plans – like alternate suppliers and flexible logistics – companies can absorb shocks more smoothly. In ANZ, we’ve seen that businesses are now prioritising resilience alongside efficiency. This includes strategies like holding “strategic inventory” of critical items and using data to predict risks (e.g. weather events, supplier financial health) before they wreak havoc. The end result is fewer surprises and faster recovery when disruptions occur.

How NetSuite powers supply chain optimisation

NetSuite’s modular design allows businesses to configure solutions that match their supply chain needs – whether it’s streamlining procurement, predicting demand more accurately, or managing warehouse operations with greater efficiency. Each module plays a critical role in ensuring supply chain resilience and operational excellence.

NetSuite Demand Planning

Accurate forecasting is essential for maintaining optimal inventory levels and avoiding costly stockouts or overstocks. NetSuite’s Demand Planning module uses advanced forecasting methods – like moving averages, seasonal trends, and exponential smoothing – to predict demand with precision. This is particularly relevant in industries like retail and manufacturing, where fluctuating consumer demand and post-pandemic disruptions have led to inventory challenges.

- Anticipate demand spikes by analysing historical data, market trends, and external factors.

- Optimise production schedules by aligning procurement and manufacturing with forecasted demand.

- Reduce excess inventory and carrying costs by fine-tuning replenishment to meet real-time demand.

NetSuite Procurement Management

Procurement inefficiencies – such as delayed purchase orders and poor supplier performance – can cripple supply chains. NetSuite Procurement Management automates requisition workflows, tracks vendor performance and enforces procurement policies, ensuring that businesses maintain consistency and compliance. For manufacturers and distributors, this means fewer missed orders and reduced procurement costs.

- Automate a large chunk of procurement tasks to eliminate manual errors and free up procurement teams for strategic supplier management.

- Track vendor performance using real-time insights to manage supplier relationships effectively.

- Ensure procurement policy compliance by automating purchase approvals and requisitions.

Learn how to make procurement a source of competitive strength with NetSuite >

NetSuite Inventory and Warehouse Management

NetSuite’s Warehouse Management System (WMS) helps businesses improve efficiency by automating slotting, putaway and order fulfillment processes. Plus, its automated replenishment functionality ensures that inventory is restocked at optimal levels to improve cash flow and reduce carrying costs.

- Maximise warehouse efficiency by automating inventory management processes, reducing errors and improving order fulfillment.

- Enhance replenishment accuracy by automating stock replenishment based on real-time inventory levels and demand forecasts.

- Reduce order processing times by streamlining warehouse operations and improving inventory visibility.

NetSuite Supply Chain Control Tower

Supply chain disruptions – whether due to economic changes, geopolitical tensions or natural disasters – are inevitable. NetSuite’s Supply Chain Control Tower provides real-time insights and predictive analytics that allow businesses to proactively respond to risks and disruptions. By incorporating external data, such as economic indicators and supplier performance, NetSuite helps mitigate supply chain risks before they escalate.

- Gain real-time visibility across the supply chain to identify potential bottlenecks.

- Respond proactively to disruptions by using predictive insights and scenario planning.

- Mitigate supply chain risks through data-driven adjustments to procurement, production, and delivery schedules.

Why the NetSuite modular approach makes sense

NetSuite’s modular approach gives businesses the flexibility to implement only the functionality they need, scaling capabilities as supply chain complexity grows. This ensures that businesses can start with core features and gradually introduce advanced modules – allowing supply chain optimisation to evolve alongside business growth.

By consolidating data across procurement, inventory, production and delivery, NetSuite helps businesses get that sought-after end-to-end visibility, automate routine processes and proactively mitigate supply chain risks.

Industry-specific supply chain insights

Different sectors in ANZ feel these supply chain challenges in distinct ways. Below we highlight recent trends in manufacturing, retail, and distribution/logistics – and why they serve to deepen the need for better demand planning, procurement, inventory management and warehouse operations.

Building resilience and smarter procurement in manufacturing

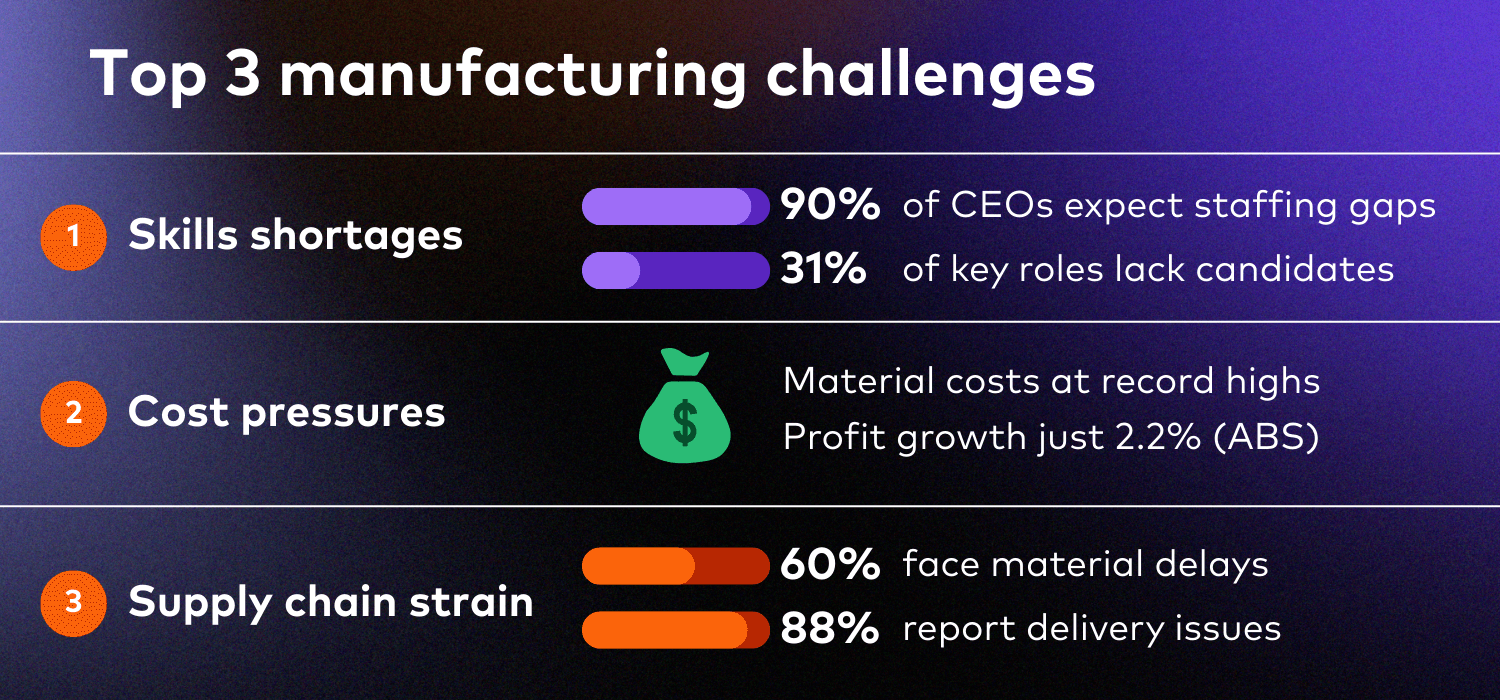

Australia’s manufacturing sector has been hit by global supply disruptions and cost pressures, exposing the need for stronger planning and supplier management. This vulnerability stems from the sector’s reliance on imported inputs – the Productivity Commission noted Australia’s import-dependence makes manufacturers especially susceptible to global shocks.

Key issues in manufacturing supply chains

- Supply chain uncertainty – Global disruptions have made supply delays and shortages more frequent, keeping supply chain volatility above pre-pandemic levels.

- Longer lead times and excess inventory – Extended lead times have forced manufacturers to stockpile materials, tying up capital and increasing storage costs.

- Escalating input costs – Rising prices for raw materials, components, and freight continue to compress margins, making strategic procurement a priority.

- Skills and technology gaps – Many manufacturers face a shortage of specialised supply chain talent and lack the digital tools needed for advanced forecasting and procurement planning.

Demand planning and inventory management challenges in retail

The retail industry in ANZ has experienced a whiplash effect – from stockouts and empty shelves during the pandemic to an inventory glut as consumer demand shifted. These disruptions have highlighted the critical need for accurate demand forecasting, agile procurement, and efficient inventory turnover to maintain profitability.

Key issues in retail supply chains

- Overstocking after shortages – Post-pandemic over-ordering left retailers with excess inventory and shrinking margins due to heavy discounting.

- Missed sales and markdowns – Slow responses to shifting consumer trends led to stockouts and markdowns, eroding profitability.

- Omnichannel complexity – eCommerce growth introduced inventory challenges with high return rates and pressure on last-mile delivery.

- Need for real-time visibility – Siloed systems make it hard to react to demand changes, driving interest in AI-driven demand planning.

Warehouse and fulfilment efficiency for distribution & logistics

On the distribution side – covering warehousing, transportation, and logistics – ANZ is experiencing both booming demand and capacity constraints. This sector underpins both manufacturing and retail and its optimisation issues revolve around space, technology and speed.

Key issues in distribution & logistics supply chains

- Warehouse space crunch – Limited space is pushing companies to optimise existing storage and improve inventory management.

- Capacity and tech upgrades – Businesses are expanding capacity and adopting new systems to enhance efficiency.

- Fulfilment challenges – Rising delivery expectations and higher costs are driving the need for faster, smarter logistics.

How modern ERP platforms are rewriting the supply chain playbook

Modern ERP platforms, especially cloud-based systems, have redefined how businesses manage complexity, shifting supply chains from reactive to predictive. By uniting procurement, inventory, demand planning, and logistics into a single, connected ecosystem, ERP platforms give businesses the control they’ve always needed but never quite had.

See everything, miss nothing

When supply chains operate in silos, problems hide in plain sight – until they blow up. Modern ERPs shatter those silos, offering real-time visibility across regions, suppliers, and inventory. A procurement delay in Auckland? A surge in demand in Sydney? ERP platforms flag these issues before they snowball, giving leaders time to pivot and prevent disruptions. This level of transparency turns decision-making into an informed, proactive process – no guesswork required.

Forecast smarter, stock smarter

Today’s ERP platforms use predictive analytics to balance supply and demand with laser precision. By factoring in historical sales, lead times and even external factors like market trends, they anticipate demand shifts long before they happen. Automated replenishment kicks in when stock hits a threshold, ensuring inventory levels stay lean without ever dipping too low. Which all adds up to fewer stockouts, fewer overstocks and a healthier bottom line.

Procurement that thinks ahead

Procurement used to be a game of spreadsheets and crossed fingers. Now, ERP platforms automate the entire process – approving purchase orders, tracking supplier performance and enforcing compliance. But it’s not just about reducing errors. With all procurement data in one place, businesses gain the insights needed to negotiate smarter deals, reduce lead times and stay ahead of potential supplier hiccups. Procurement becomes less of a paper-pushing function and more of a strategic advantage.

Warehouses that move as fast as your customers

Speed is the name of the game in warehousing and fulfillment. Modern ERPs don’t just track inventory – they optimise every step of the warehouse process. Automated putaway, barcode scanning, and real-time stock counts keep fulfillment humming along, while intelligent routing ensures deliveries hit the mark. Whether it’s managing a high-volume eCommerce operation or juggling multi-channel inventory, an ERP keeps warehouses running like clockwork – no wasted space, no wasted time.

Built for growth, ready for anything

Cloud ERP platforms are built for change. Need to scale up for peak season? Expanding into new regions? Adding new product lines? Cloud systems flex as the business grows, adding capacity and functionality without the headaches of traditional IT. And because they’re always up to date, businesses stay ahead of shifting market conditions with features that evolve alongside their needs.

Ready to transform your supply chain?

Speak to Annexa to learn how NetSuite can future-proof your operations.

Learn more:

- How NetSuite streamlines supply chain operations – end to end >

- How NetSuite transforms inventory into a competitive advantage >

- Make procurement a source of competitive strength with NetSuite >

- A closer look at NetSuite Supply Chain Control Tower >

- Real-world use cases of NetSuite Demand Planning >