Despite the reliance on siloed systems or rigid on-premises ERPs in manufacturing, digital transformation is rapidly gaining traction, mirroring trends seen across other industries. This shift is fuelled by the recognition that digitisation offers transformative benefits, ushering in a new era of competitive capabilities and value creation.

For example, cloud-based supply chain solutions provide manufacturers with real-time visibility into inventory levels, demand forecasts, and supplier performance across multiple locations. Similarly, Artificial Intelligence (AI) plays a pivotal role by automating repetitive tasks and analysing extensive datasets to discern trends, optimise production schedules, and forecast demand with heightened accuracy.

To sustain these new levels of speed, agility, efficiency, and precision, manufacturers must embrace digital technologies that will open the door to innovation, streamlined operations, and resilience. It’s either that or get left behind.

At Annexa, we know that manufacturing companies can successfully make the leap when they put in place customised cloud ERP solutions. As NetSuite ERP solution partners, we’ve helped ANZ companies make these big moves and witnessed just how transformational the process can be.

In this blog, we explore NetSuite manufacturing solutions, why cloud-based NetSuite is already so popular among manufacturers, how it provides several important advantages, and the impact it has on manufacturing operations when properly deployed.

NetSuite manufacturing fundamentals

Let’s begin with a little about NetSuite, that popular suite of cloud ERP solutions covering financial management, supply chain management, inventory management, and customer relationship management (CRM).

Although NetSuite caters to a wide variety of industries, the nuances of manufacturing – from plant and mill operations to factory assembly lines – require a flexible approach to meet the distinct requirements.

Why NetSuite for manufacturers?

Is NetSuite good for manufacturing? With NetSuite’s core, manufacturers can efficiently manage their finances, automate business processes, nurture customer relationships, and seamlessly conduct eCommerce transactions, all within a single, unified system. But NetSuite’s extensible platform also delivers powerful industry-specific functionality, third-party integration compatibilities, additional modules, and apps to finetune even the most particular process in manufacturing.

The main challenges facing the light manufacturing industry and how to rise above them >

What are the benefits of NetSuite for manufacturers?

Here are some top-line benefits of NetSuite:

- Improve operational effectiveness | Streamlining all processes, from order to cash, through a single unified system, NetSuite enables manufacturers to operate more efficiently.

- Reduce ‘cost to produce’ | By optimising manufacturing processes and improving resource utilisation, NetSuite helps lower the overall cost of production.

- Faster time to value | With an integrated solution, manufacturers can expect a quicker return on investment due to improved efficiencies and reduced lead times.

- Unified solution | NetSuite offers a comprehensive system that reduces reliance on third-party applications and provides all necessary tools within one platform.

- Improve quality, service, and through-put | The system enhances product quality and customer service while managing throughput effectively.

- Variance management | NetSuite allows manufacturers to compare actual performance against standard benchmarks to identify and manage variances.

- One version of the truth | It ensures data consistency across the enterprise, providing a single source of truth for better decision-making.

- Integrate plant to enterprise (P2E) | NetSuite facilitates the integration of shop floor operations with enterprise-level management systems.

- Manufacturing information and intelligence | The platform offers valuable insights and analytics, helping businesses to manage more profitably.

There are also a number of functional features that cater to the more intricate requirements of manufacturing:

- Advanced planning and scheduling | Tools to effectively plan and utilise shop floor resources, aiming to reduce operating costs.

- Discrete/assembly manufacturing | NetSuite caters to the specific needs of discrete and assembly manufacturing, offering features such as configurable work order logic and enhanced data collection.

- Batch or process manufacturing | For batch or process manufacturers, NetSuite includes functionalities like FIFO material issuance and comprehensive batch lot tracking for quality control and compliance.

- Mobile capability | It supports barcode scanning and tablet functionalities for real-time MES reporting, which is essential for on-the-go data entry and operational control.

- Extended setup criteria | NetSuite can be configured to suit various manufacturing environments, improving the efficiency of work order release and other processes.

A few more helpful resources:

The top 10 manufacturing ERP features your business needs >

Why manufacturers need NetSuite as their business management solution >

How discrete manufacturing ERP systems support operational agility >

What are the industry-specific NetSuite modules for manufacturing?

NetSuite Manufacturing Edition offers three core options to help you deploy manufacturing functionality:

Work Orders & Assemblies works best for companies that do some light assembly but don’t need to track work in process or the labour separately.

WIP & Routings adds the ability to define work centres, routings, track labour costing, infinite capacity scheduling and provides a Gantt chart with drag-and-drop functionality.

Advanced Manufacturing provides for those looking for complete control of all aspects of their manufacturing processes, including finite capacity scheduling, quality management, and manufacturing execution.

Let’s explore each in a little more detail.

The NetSuite Work Orders and Assemblies module

Ideal for: Businesses with simpler manufacturing processes, such as light assembly

Features: This level allows for the creation and management of work orders and the assembly of products without the need to track Work in Process (WIP) inventory or labour costs separately. It’s a more basic version suitable for companies that don’t need detailed manufacturing operations management.

- Easy set-up – up and running in days

- Automatic back flushing of components

- Real-time costing

- Ability to manufacture without work orders

- Support lean initiatives

- Review and analyse production plans based on actual production times

NetSuite WIP and Routings module

Ideal for: Companies that need more detailed tracking and management capabilities.

Features: This option adds functionalities such as the definition and management of work centres (specific locations where work is performed), the ability to define and manage routings (the path that a product follows through the manufacturing process), labour costing, and infinite capacity scheduling. It also includes a Gantt chart view for better visual management of schedules, providing a graphical representation of the production timeline.

- Work centre management

- Accurate costing

- Infinite capacity scheduling

- Drag-and-Drop GANTT style scheduler

- Track Work In Process costs

- Review and analyse production plans based on actual production time

NetSuite Advanced Manufacturing module

Ideal for: Businesses seeking comprehensive control over all aspects of their manufacturing processes.

Features: This is the most powerful vertically integrated solution built to work natively with the core NetSuite ERP platform. Advanced Manufacturing includes all the features of WIP & Routings but also adds finite capacity scheduling (a method that ensures production activities are scheduled based on resource constraints) and manufacturing execution (the execution layer of a manufacturing system that ensures products are built efficiently and to specification). This is the most comprehensive solution for manufacturers that require an in-depth and granular approach to production management.

- Improve operational effectiveness

- Reduce ‘cost to produce’

- Faster time to value

- Unified solution – reduce reliance on third parties

- Improve quality, service, and through-put

- Variance management: compare actual versus standard

- Integrate plant to enterprise (P2E)

- Manufacturing information and intelligence

NetSuite Quality Management module

Designing, manufacturing, distributing and selling a product of high quality doesn’t happen by accident; it requires a company-wide commitment to enforce policies and standards. NetSuite’s Quality Management solution has been designed to help you deliver the highest quality in your products with minimal overhead regardless of the size and complexity of your business and product line.

- Collect in-process and incoming inspection results

- Compare to pass/fail criteria

- Integrated non-conformance reporting

- Reduced cost of quality

- Formalise quality policies, standards, and practices

- Improve product quality

- Initiate quality activities from business transactions

- Work with large volumes of raw data sets

NetSuite Manufacturing Execution

Obtaining information from your production facilities, regardless of location, is vital to the short-term execution of your business and your long-term strategic planning. NetSuite offers both a traditional barcode scanner-based interface and an innovative and interactive tablet app. While the barcode scanner is designed for the speed of data entry, the tablet features a rich interface that provides unparalleled feedback about what’s happening in the user’s work centre and/or machine.

- Easy-to-use but powerful functionality increases user satisfaction and increases data accuracy

- Real-time updates from manufacturing enabling you to make educated decisions that affect your business operations

- User configurable tablet application allows the user to optimise the system on the fly

- Native application designed from the ground up as part of Advanced Manufacturing

- Issue materials, enter production, record downtime and identify quality issues as they happen

NetSuite Demand Planning module

NetSuite’s native demand planning module is specifically designed to provide the user with the ability to predict required inventory based on historical demand or sales forecasts. This offers the right balance of powerful functionality and ease-of-use to help you manage your inventory more efficiently.

- Reduce costs with order consolidation

- Simplify the ordering process

- Workflow approvals

- Optimise inventory levels

- Increase turns

NetSuite Warehouse Management System module

With intelligent pick-and-pack processes, handheld barcode scanning, cycle counting and integration with shipping systems, you’ll run your warehouse more efficiently and minimise handling costs with NetSuite WMS. It can guide users through important tasks, from receiving and storing items to picking and shipping them, in the most efficient way. As items are processed in the warehouse, each transaction is automatically updated in the NetSuite inventory record and reported in real time.

- Track inventory in real time as it enters, labour moves throughout, and exits the warehouse

- Ease inbound data capture using mobile device barcode scanning

- Optimise space utilisation and easily select the most appropriate storage

- Improve pick path efficiency and opportunistic multi-order picking

- Minimise mis-picks and inaccurate fulfillment with data validation

What are NetSuite integrations for manufacturers?

NetSuite’s integration capabilities facilitate seamless communication and data flow across various business systems and manufacturing technologies. In fact, NetSuite can be connected with any third-party system.

For example, NetSuite can seamlessly integrate with Manufacturing Execution Systems (MES), allowing for the automatic exchange of production data between shop floor operations and ERP systems. This integration streamlines workflows, reduces manual data entry errors, and improves overall efficiency in manufacturing processes.

Or integrating NetSuite with Product Lifecycle Management (PLM) software will enable you to manage product development lifecycles, from concept to launch. By syncing data between PLM and an ERP, manufacturers can improve collaboration, track product iterations, and accelerate time-to-market.

You can also integrate with IoT devices to gather real-time insights from connected machinery and equipment, optimising asset utilisation, predicting maintenance needs, and minimising downtime.

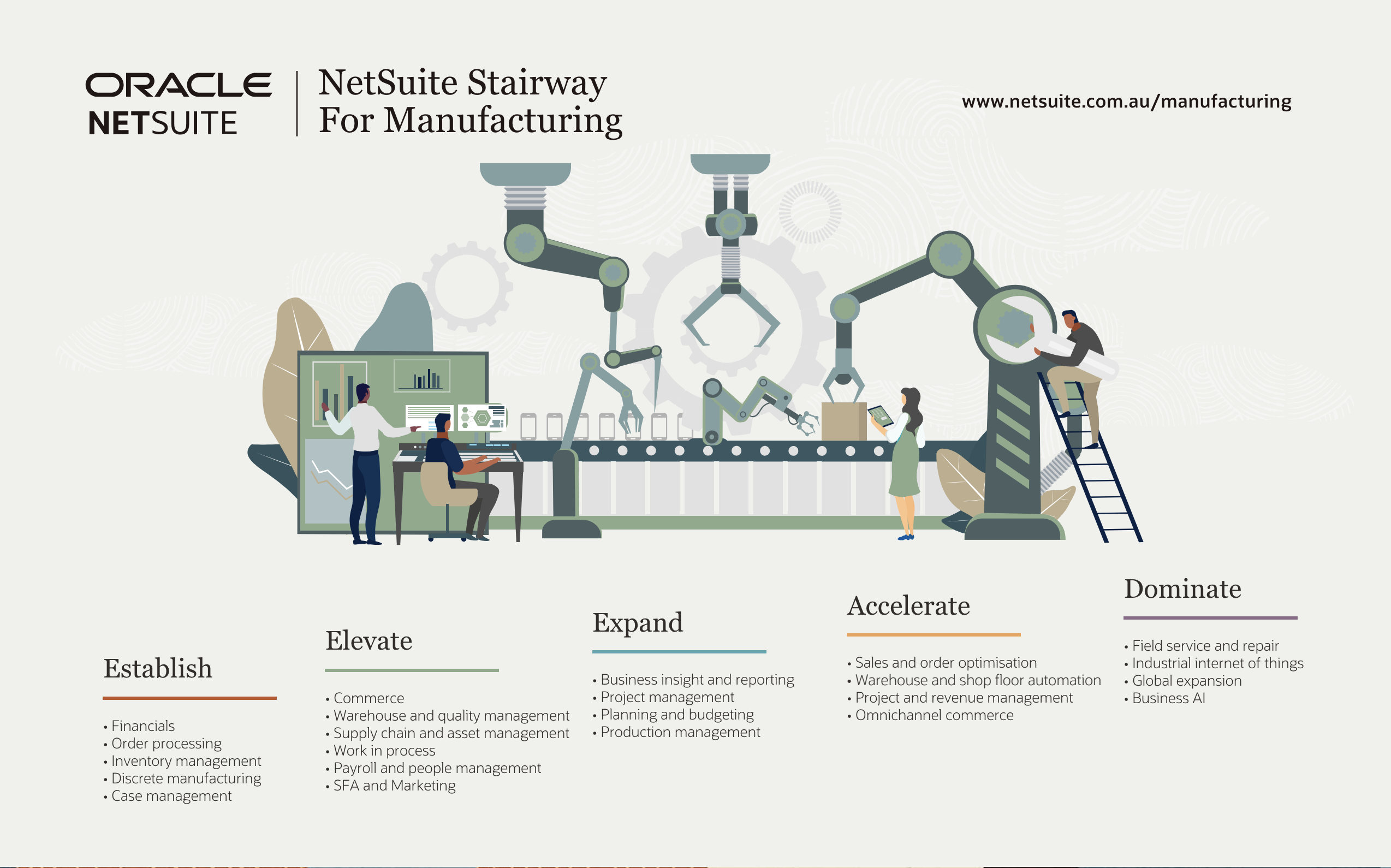

What is NetSuite SuiteSuccess for manufacturers?

Leveraging its extensive experience in partnering with manufacturing companies, NetSuite has developed a tailored deployment solution to address the specific challenges of the manufacturing industry. Known as SuiteSuccess, this approach combines industry expertise with best practices crafted by NetSuite’s dedicated manufacturing team. SuiteSuccess is designed to:

- Deliver the ideal NetSuite implementation by phasing out costly, outdated, and unruly systems using a prescribed stairway methodology.

- Achieve faster time to value, increased business efficiency, flexibility, and greater success.

- Optimise business processes with tailored features, designed to meet the dynamic needs of manufacturers.

Planning for implementation of NetSuite for manufacturers

Before implementing, you will need to develop a thorough understanding of the manufacturing workflows and processes within your organisation. Start by conducting comprehensive process mapping sessions that involve key stakeholders from different departments, including production, inventory management, quality control, and procurement. This will help identify key areas where NetSuite can streamline operations and improve efficiency and ensure alignment with business objectives.

Best practices for inventory management in manufacturing & logistics >

Why you need a NetSuite manufacturing implementation partner

For expert guidance, involve a NetSuite partner early in the planning stages. This will be particularly invaluable when it comes to selecting the right NetSuite products, exploring NetSuite licensing options, and tailoring the platform to accommodate any unique manufacturing processes, such as discrete manufacturing, process manufacturing, or mixed-mode manufacturing.

Choosing a NetSuite partner with in-depth knowledge of best practices for implementing NetSuite in manufacturing will also help with:

- Proactively addressing common challenges during implementation and strategies to overcome them

- Identifying opportunities for process optimisation, automation, and integration with NetSuite

- Hands-on support throughout the implementation journey, from project planning to post-implementation support

- Guidance on configuring modules, setting up workflows, and integrating third-party applications

- Valuable recommendations on system configuration practices based on their experience working with similar manufacturing clients

- Strategising for data cleansing, validation, and mapping to ensure accuracy and consistency post-implementation

- In-depth planning for integration with existing systems like MES, PLM software, or IoT devices to facilitate real-time data exchange and visibility across the manufacturing ecosystem

- Assistance with training and change management to ensure successful adoption after go-live

- Ongoing support, advice, and optimisation services to maximise the value of your NetSuite investment over time

Are you ready to explore how NetSuite can transform your manufacturing business?

Contact us today to discuss your needs and discover how we can tailor NetSuite to your unique business requirements.